STill Wine Services

Full Production

Still WIne Services

Grape-to-Bottle Services

You provide the grapes and our winemaking team will help you develop an outstanding still wine, following your protocol. As a full-production custom crush winery, we do all crushing, processing, necessary lab work and fermentation on site. We will then finish the process with bottling, labeling, packing and paletizing your wines for pick-up at our facility.

Bottling

Our wine production facilities offer state-of-the-art, fully automated bottling, labeling, and packaging of your wines. If you would like to schedule a tour of our facility to see our capabilities up close, let’s schedule a visit to discuss your needs. Contact us!

Fully Automated

Still Wine Bottling

•Fast •Efficient •State-of-the-Art

If you are in need of rapid still wine bottling and packaging production, we’ve got you covered. Our cutting-edge wine bottling production facilities in Healdsburg, California offer the following capabilties:

FAST & FULLY CUSTOMIZABLE

High-Output Capacity

150-bottles per minute | 6,000 cases in 8-hours

Customizable Bottle Formats

375ml, 500ml, and 750ml

QUALITY CONTROLLED

Strictly monitored from wine chemistries to packaging.

Five skilled operators per shift run the line.

Dedicated Quality Control Tech oversees each production run to ensure highest quality standards are met.

Automated Bottling

How it Works

FILL HEIGHT & CLOSURE SYSTEM

Bottles are cleaned, filled and scanned through a sophisticated laser Vision System which performs inspections of bottle fill height. The system then checks that filled bottles exiting the Fill Height and Closure System have properly positioned corks or screw caps. Any bottles not meeting requirements for fill height or missing proper closures are rejected, accumulated and audited by quality control personnel.

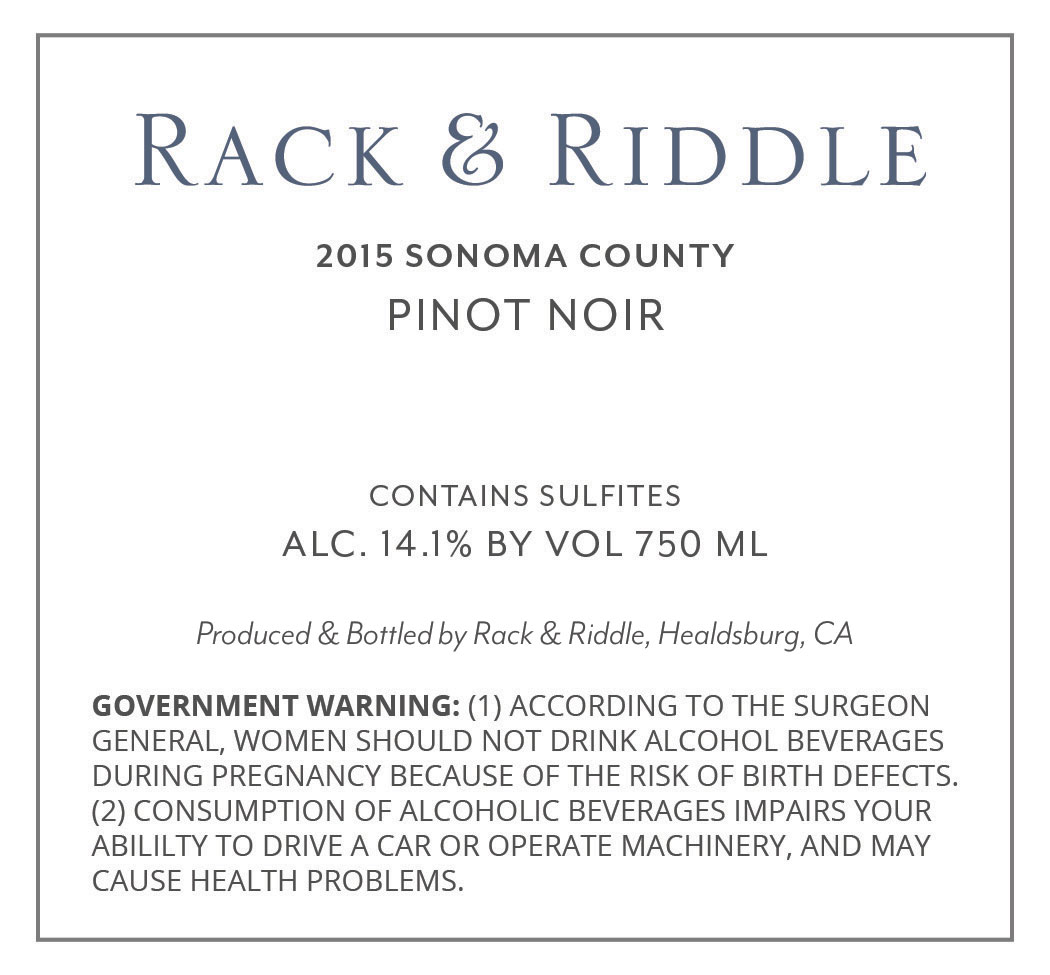

LABEL INSPECTION SYSTEM

Once filled, foiled and labeled, four precision cameras capture 360-degree views of each bottle, inspecting for correct label information, placement, defects (such as wrinkles or air bubbles), doubled labels or flagged corners.

PACKAGING

The system automatically separates bottles from cases, sending cases to an overhead conveyor and bottles into a filler. The Automatic Case Packer packs two 12-pack cases of wine at a time, seals the cases, weighs them, and rejects any that are underweight (missing bottles). Cases are tagged with ID labels then automatically palletized, based on a specific pallet configuration set by the operator for each run. Pallets are then wrapped for transport by an automatic wrapping mechanism, where a printed pallet ID tag is applied.

Still Wine Label

Specifications

Following are specs for still wine bottle labels:

Position 4 — label off left

Separate front and back rolls required

Max OD: 12.5″

Core diameter: 3″

The Best of All Things Sparkling™

LET'S COLLABORATE

Learn more about how we can assist you with sparkling or still wine production. We're here to help.